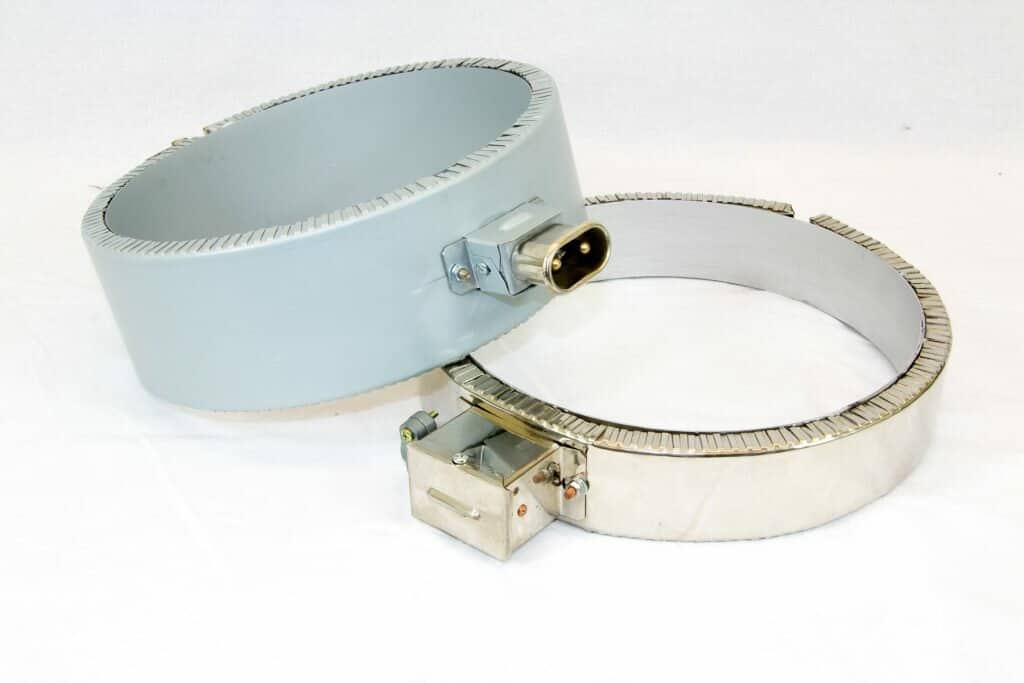

Mica Band Heaters are very commonly used within the plastics industry for extrusion injection moulding and blow moulding. The heater sits over cylindrical metal pipework or a barrel to heat the contents from a solid state to molten liquid. Band heaters are thin and therefore great for effective heat transfer. They are capable of reaching maximum temperatures of 300°C.

The construction of a standard mica band heater consists of resistance wire which is wound with even spacing over a flexible mica insulator to form the element interior. This is then covered by additional mica insulation on each side and fitted into an outer metal casing before the assembly is formed to the required diameter. We ensure the inside surface is smooth and consistent in shape to avoid any hot spots or poor fitting. Band heaters are made to order as they vary in size and power. The area of which the heaters are used is often exposed to liquids and therefore the leads can be complete with protective cable. Leads can be fitted from the face or the edge of the heater to facilitate the fitting of heaters in areas where space is limited. Leads can also be fitted from a terminal housing if required and metal braided sleeve for additional protection.

Ceramic Knuckle Band Heaters are used for applications that require higher temperatures than that of a mica band heater. The ceramic knuckle heaters are capable of reaching temperatures of up to 450°C.

Mica Nozzle Heaters are small in diameter and used for low to medium temperatures, up to 300°C.

Please provide the following information when sending us your enquiry: Quantity, Inside Diameter, Width, Voltage, Wattage, Lead Length, Lead Type and the position of which they exit the heater.

Click here to make an enquiry about Band Heaters

- Rubber Moulding

- Extrusion Machines

- Plastic Process Machinery

- Packaging Machinery

- Tooling & Die Heads

- Food Process Machinery

- Laboratory Equipment / Test Equipment